Langjing Factory Quality Control Standard Process

Langjing Technology Company manufactures PC speaker, gaming speaker, bluetooth speaker etc follows the the quality standard during the production process :

1.Design and Prototyping:

3D Modeling and Prototyping: Engineers create a 3D model and develop a prototype to test functionality, aesthetics, and performance.

2.Material Procurement:

Sourcing High-Quality Components: Ensure that all components, such as speaker drivers, amplifiers, circuit boards, and batteries, are sourced from reliable suppliers with CE RoHS FCC etc certification.

3.Assembly:

Manual and Automated Assembly: Components are assembled, which includes mounting the circuit board, attaching speaker drivers, and connecting the battery.

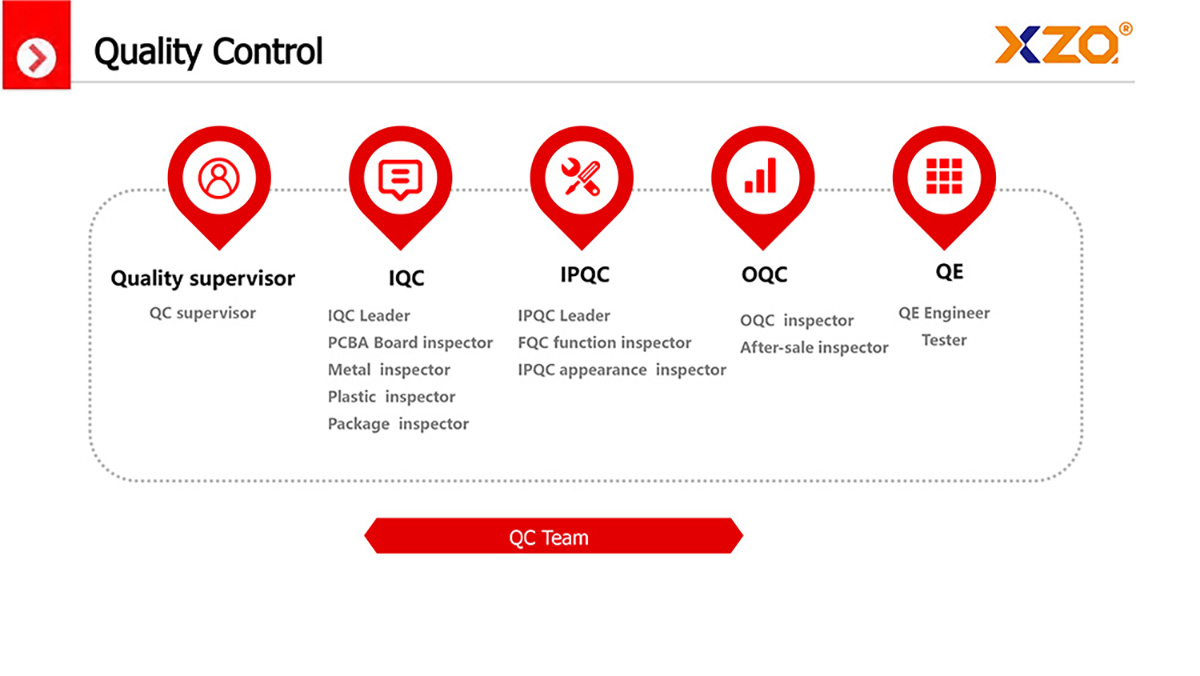

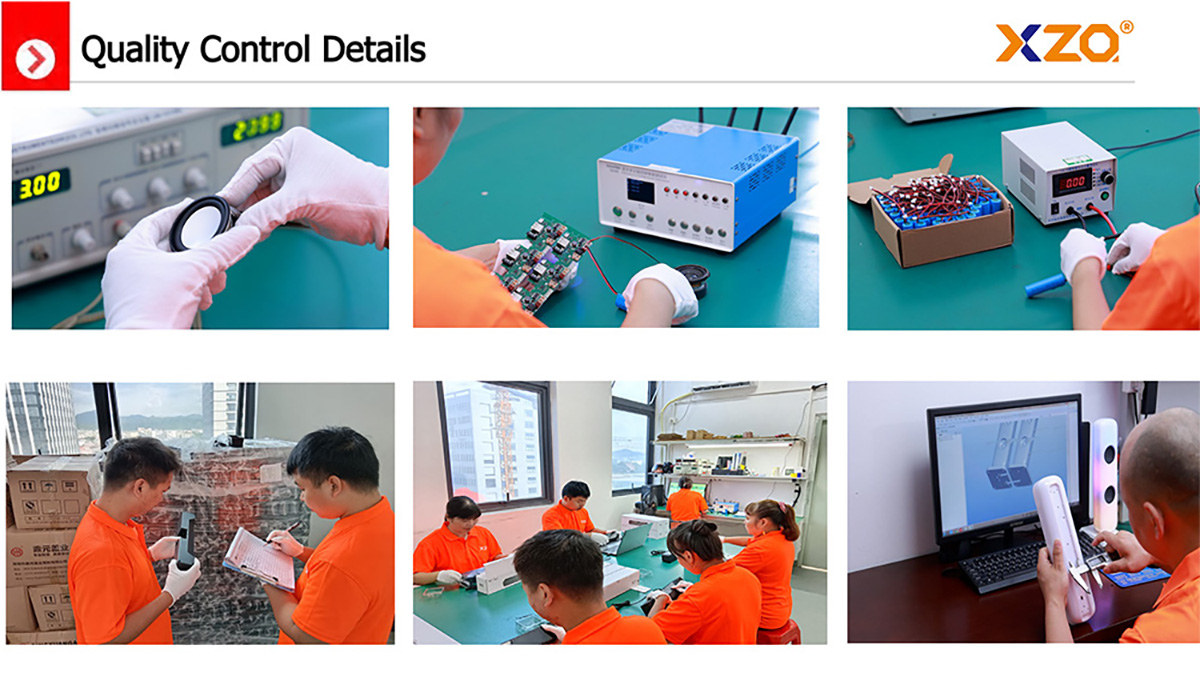

4.Quality Control Checks:

①Functional Testing: Verify that all components work correctly.

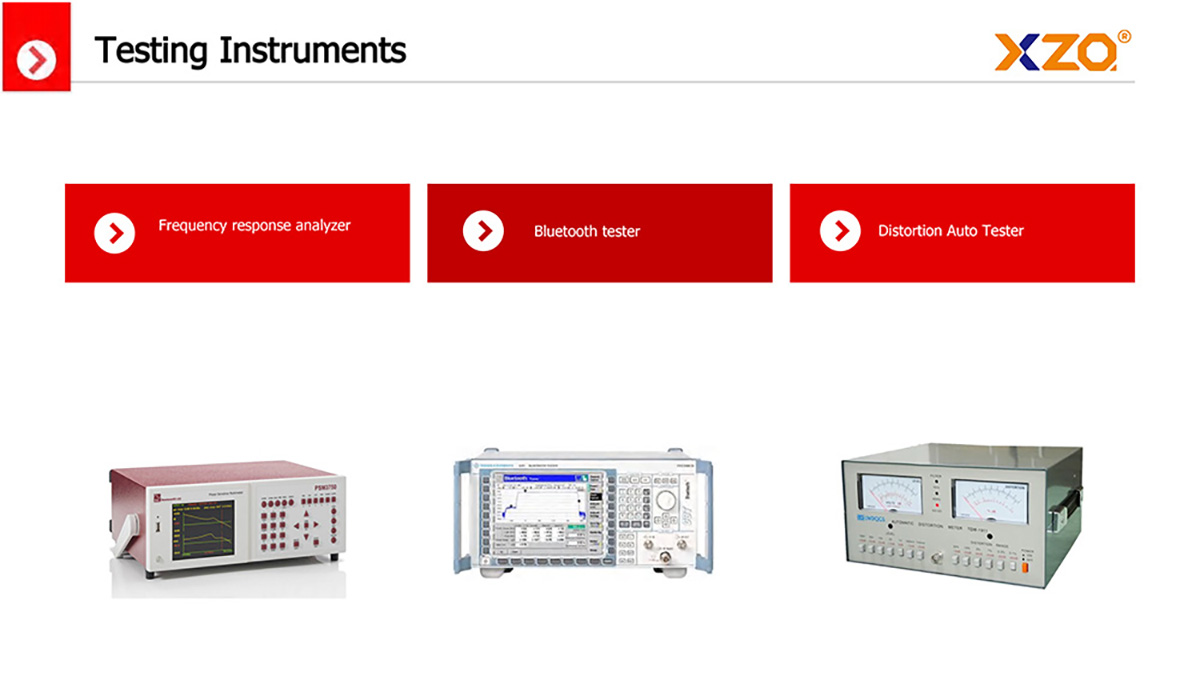

②Sound Quality Testing: Ensure the sound output meets the desired standards.

③Inspection for Defects: Check for any cosmetic flaws or defects.

5.Performance Testing:

①Bluetooth Connectivity: Test the Bluetooth connection for stability and range.

②Battery Life: Ensure the battery meets the required performance standards.

③Durability Testing: Test the speaker’s durability under various conditions

6.Packaging:

Protective Packaging: Use suitable packaging materials to protect the speakers during transportation.

By following these steps and continuously improving processes, Langjing manufacturers can ensure that Bluetooth speakers meet high-quality standards and performance criteria.

If you have any specific aspect of the production process you’d like to develop deeper into, feel free to ask!